Convertible Hood Cleaning and Restoring

Soft-tops used to be the norm for all cars but in the modern age they are reserved for the sporty or high-end vehicles. Hood technology has also moved on since the roaring twenties and now most modern cars have three or more layer roofs built by the Haartz corporation on behalf of vehicle manufacturers.

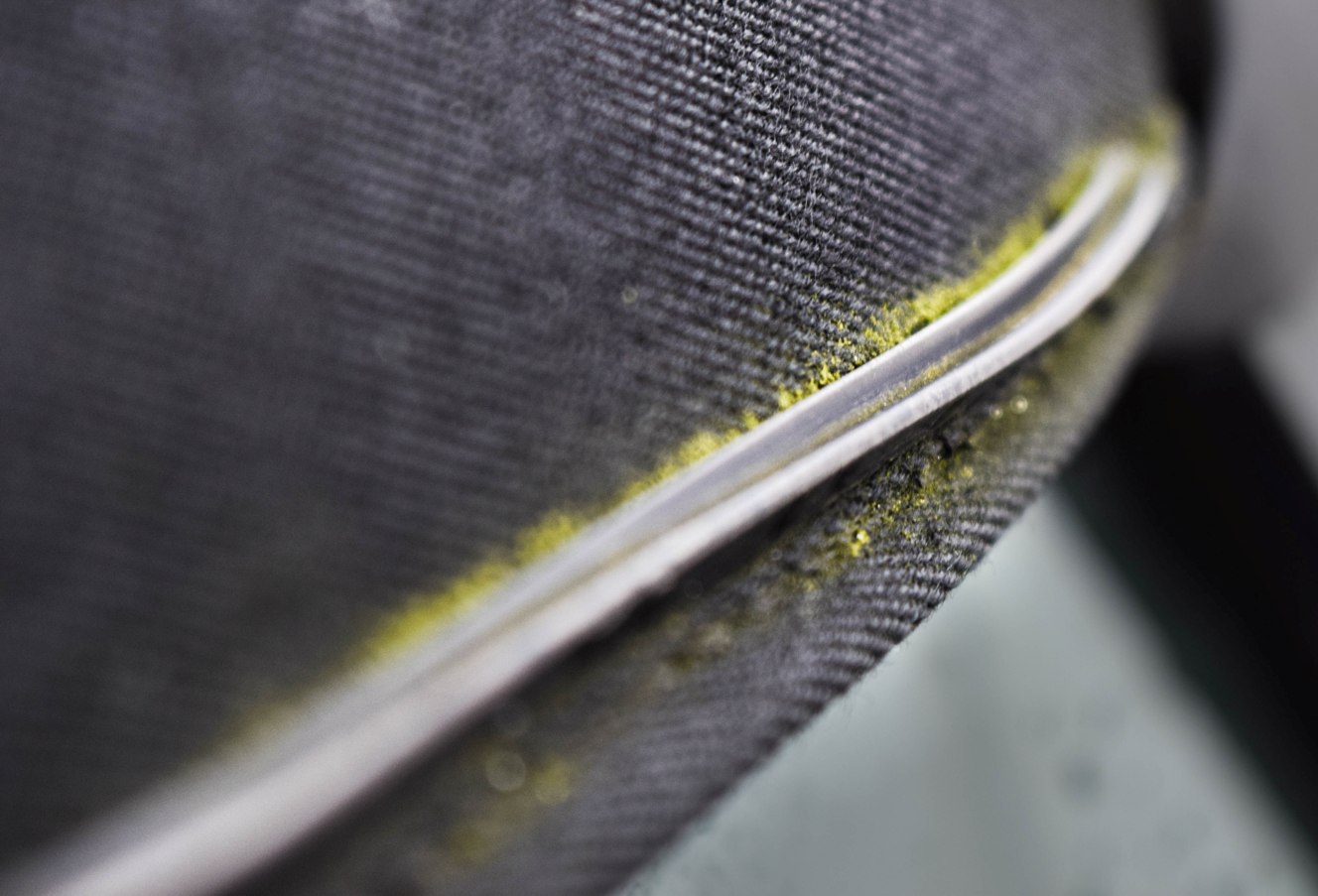

Over time, algae and fungus gets into the upper layer of fabric and makes them go green. Though modern hoods rarely leak as a consequence, in extreme cases if left uncared for it can lead to lasting damage. Equally, the colouring in the fabric can decay over time, mostly due to UV damage leading to the colour fading – often blacks turn grey for example.

A detailer can restore hoods effectively, but it has to be done correctly in order to avoid damage and to result in long lasting benefits. The first step is a deep clean, not only of the top layer of the hood, but also the area in between the top and waterproofing layers. Soft brush attachments for DA polishers (not rotary polishers or drills as these can cause damage) can help the process, as can steam cleaners and hot water pressure washers. You have got to be careful not to simply push the fungal spores deeper into the fabric – they have to be obliterated otherwise they will return quickly once the sun comes out.

Once clean there are various products you can apply to re-dye the hood – Renevo is a leading brand in this market, though there are others, some of whom offer a wider range of dye colours. All the dyes need to applied to a completely dry surface – so for those without garages it can be difficult to create the right environment for the process.

Once dyed with one or more coats, it is usually necessary to add protection, though some dye products claim to offer an element of protection. The best products are dedicated to protection and create a hydrophobic coating – thus water simply beads off the surface rather than being absorbed. The protection also adds UV filters, thus the hood won’t fade again unless the protection isn’t replenished at the correct intervals or is removed prematurely with incorrect wash methods.

Issues 1 and 4 of the PVD Pro Detailer magazine have in-depth articles on this topic and are well worth a read if you want to attempt the process yourself.